Adhesive wheels

A holding wheel consists of a permanent magnet system with variable fine or two-pole pitch.

Ferromagnetic sheets, tubes, bars, profiles, etc. are transported in rolling mills, drawing shops, hardening shops; forming and electroplating plants safely and without slippage even at high speeds with adhesive wheels. The use of self-adhesive wheels is advantageous for feeding and discharging sheets as well as transporting sheet waste in fully automatic or semi-automatic punching machines or presses in sheet metal processing plants.

As rollers of flame cutting machines, adhesive wheels enable transport on steep surfaces, even overhead.

Application area

Application range permanent magnetic holding wheels

Permanent magnetic holding wheels are particularly suitable in sheet metal processing, for fully or semi-automatic punching or pressing operations and for sheet metal presses. They also stand for wear-free operation and operational reliability without power supply.

Versions

Adhesive wheel versions

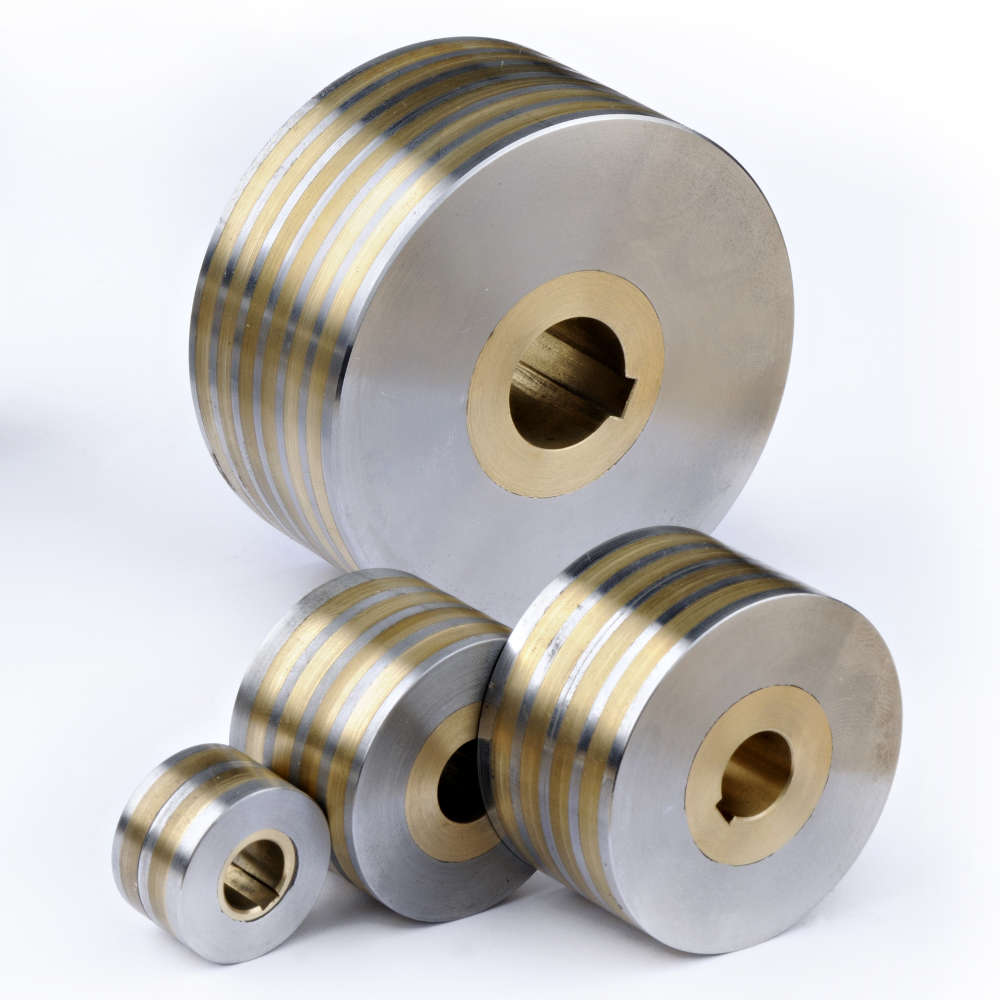

Adhesive wheels with smooth tread are manufactured in four standard versions: Holding wheels with two-pole pitch and holding wheels with multi-pole pitch.

Holding wheels with two-pole pitch are designed for transporting workpieces with a wall thickness greater than 2 mm. The holding forces specified in the dimension tables are achieved when the sheet thickness corresponds approximately to the pole width of the roll. Holding wheels with multi-pole grid are suitable for sheet thicknesses below 2 mm.

- Type series 100900

HF holding wheels with a two-pole pitch, built using hard ferrite magnets.

- Type series 100400

AlNiCo holding wheels with a two-pole pitch, built using Alnico magnets.

- Type series 140100

REFeb holding wheels with a two-pole pitch, built using neodymium magnets.

- 101500 series

HF holding wheels with a multi-pole pitch, built using hard ferrite magnets.

We will gladly manufacture “your” holding wheel according to your requirements and application specifications.

Special shapes and profiles are possible. In case of heavy paint or rust deposits on the conveyed material, a loss of the holding force is to be expected.

Functionality

How the adhesive wheels work

The closely spaced poles of the holding wheel ensure that the magnetic force lines flow through the workpieces to be conveyed without magnetic saturation and thus without loss of holding force, even with the smallest wall thicknesses. This ensures secure adhesion of the parts.

The parts are moved gently, as there is no slippage, over the wheels and fed to or from the machining process. Here, the workpieces can be guided both horizontally and vertically. Suspended transportation is also possible in many cases