Service

Maintenance and Repair

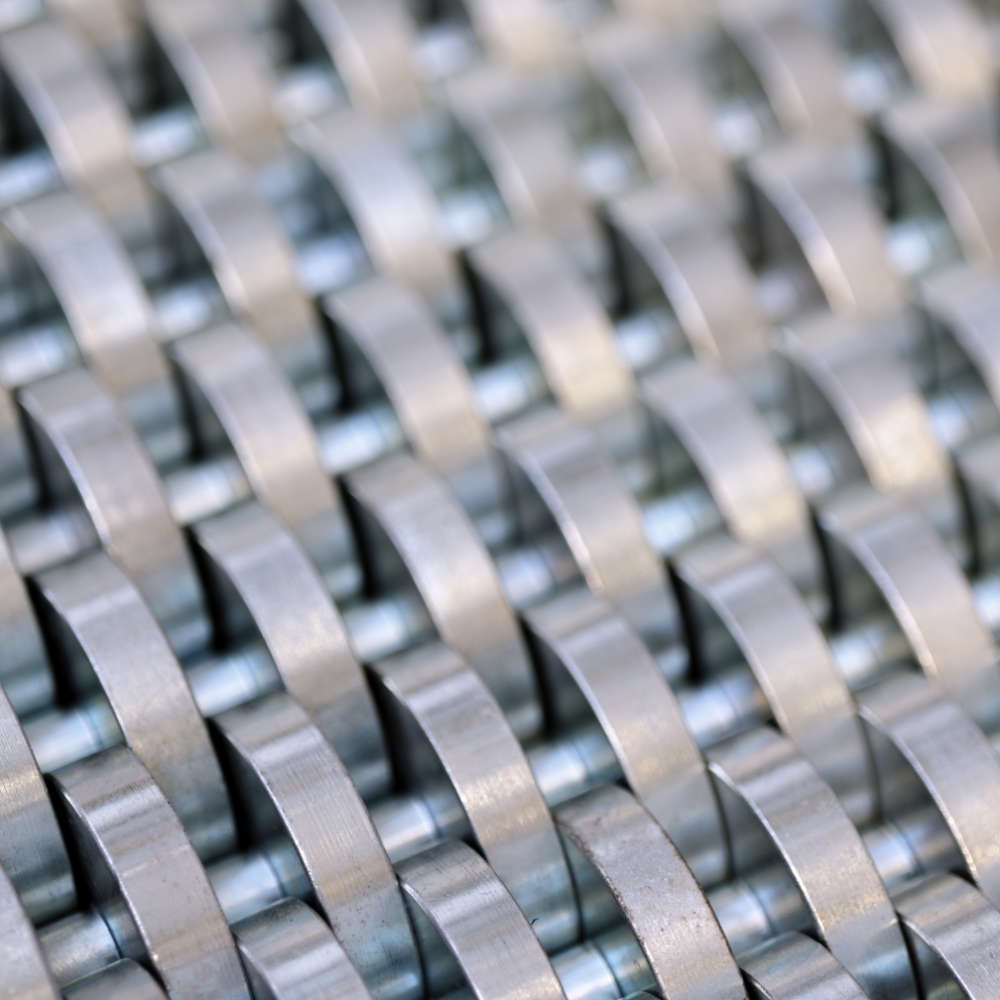

Efficient and reliable.

Maintenance and Repair of Tridelta Magnet Systems

are a leading solution in the world of magnet technology and are used in a wide range of applications. To ensure that these magnet systems always work efficiently and reliably, regular maintenance and, if necessary, repair is essential. On this page, you will learn more about the importance of these measures and how they can best be implemented.

Why is maintenance important?

Maintenance of Tridelta magnetic systems is critical to ensure their optimum performance and longevity. These systems are precision manufactured and often operate in demanding environments. Without proper care, they can lose efficiency or even fail. The effects can vary, from reduced performance to costly downtime in production or operation.

Regular maintenance steps:

- Visual Inspection: Begin a visual inspection of the magnetic system to determine any obvious damage, cracks, or contamination. Also check the connections and fasteners for strength.

- Cleaning: Remove any dirt, dust or debris from the magnet surfaces. Use a suitable cleaning agent for this and dry the surfaces carefully.

- Checking the electrical connections: Make sure all electrical connections are tight and have no corrosion. Loose connections can lead to a loss of power.

- Magnetic field testing: Use special test equipment to check the strength and homogeneity of the magnetic field. Deviations from specifications may indicate problems.

- Heat monitoring: For magnet systems that are used intensively, you should monitor the temperature regularly. Overheating can affect performance and cause damage.

Repair of Tridelta Magnet Systems:

If problems or damage are found during maintenance, immediate repair is required. It is advisable to have repairs carried out by professionals who have the necessary knowledge and experience to repair Tridelta magnet systems properly. The most common repairs include replacing damaged magnets, repairing electrical connections, and fixing mechanical problems.

Summary:

Maintenance and repair of Tridelta magnetic systems are crucial to ensure their optimal performance and service life. Regular inspections and maintenance can identify and correct potential problems early, preventing costly breakdowns and repairs. Rely on qualified professionals to perform repairs and follow the manufacturer’s recommended maintenance intervals to ensure the reliability of your Tridelta magnetic systems.