Hysteresis brake

The hysteresis brake also generates braking force at standstill.

This makes it particularly suitable as a holding brake.

Advantages/Properties

- wear-free, since contactless

- Electroless, which means: fail-safe, low-maintenance, sustainable

- no follow-up costs

- High braking force even at low speeds

- noiseless

Application hysteresis brake

This type of brake is used wherever rotating parts are to be braked constantly with the same force irrespective of their speed or where braking force is required even when parts are stationary or in the event of slippage. Since the hysteresis brake also produces a braking force at standstill, it is suitable as a holding brake.

Classic field of application

- Medical Technology

- Packaging machines

- Tension control for thread, wire, cable, rope, foil, paper, film and tape tensioners

- Printer, Copier

- ATMs and vending machines such as ticket vending machines

The special feature of this design is that it provides a braking force even when stationary. This makes it particularly suitable as a holding brake!

Product description

Hysteresis brake function

It operates wear-free, maintenance-free, contactless and has an almost unlimited service life under normal conditions.

Hysteresis brakes are suitable if a constant torque is to be transmitted over large speed ranges

Functionality hysteresis brake

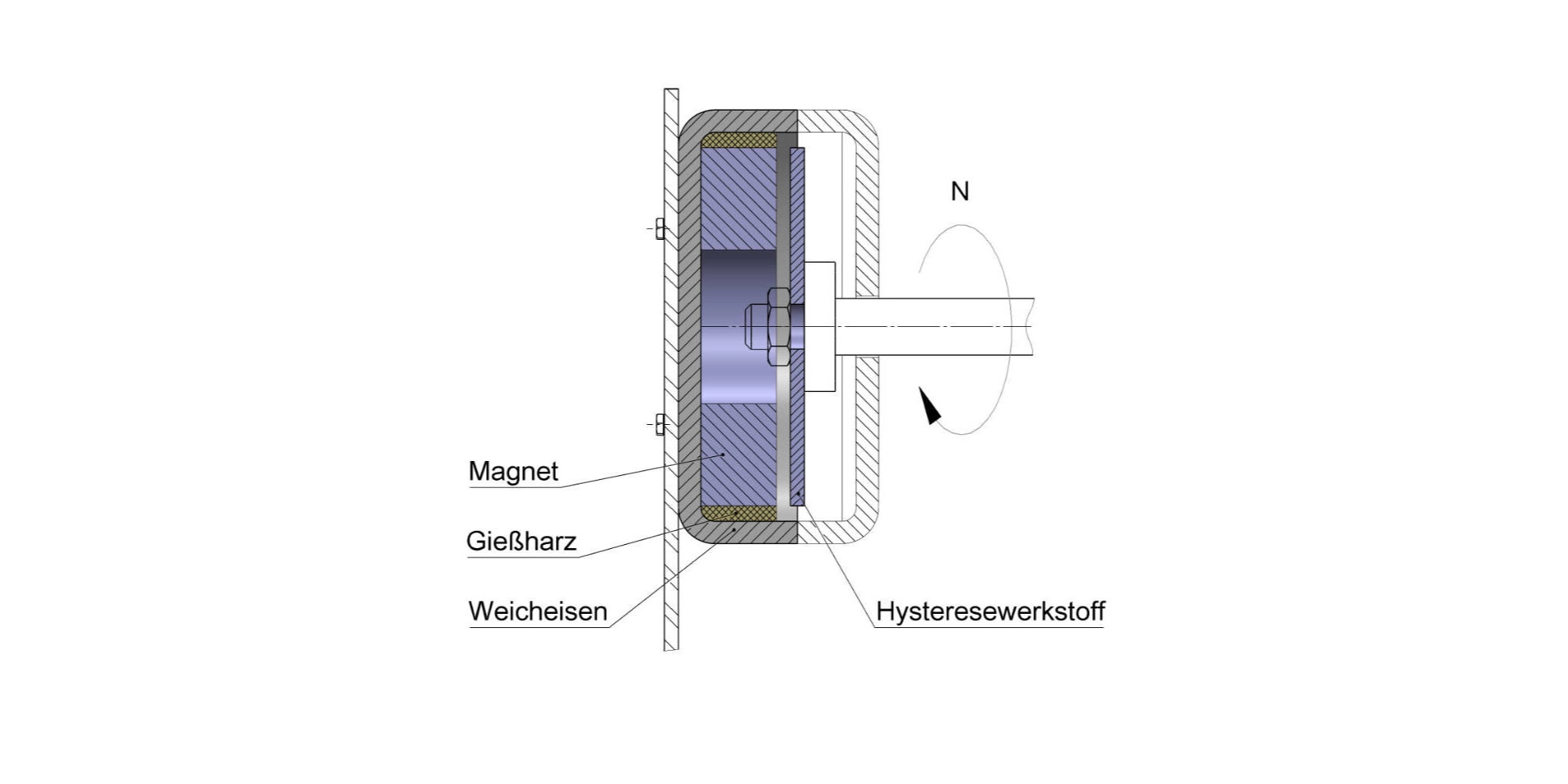

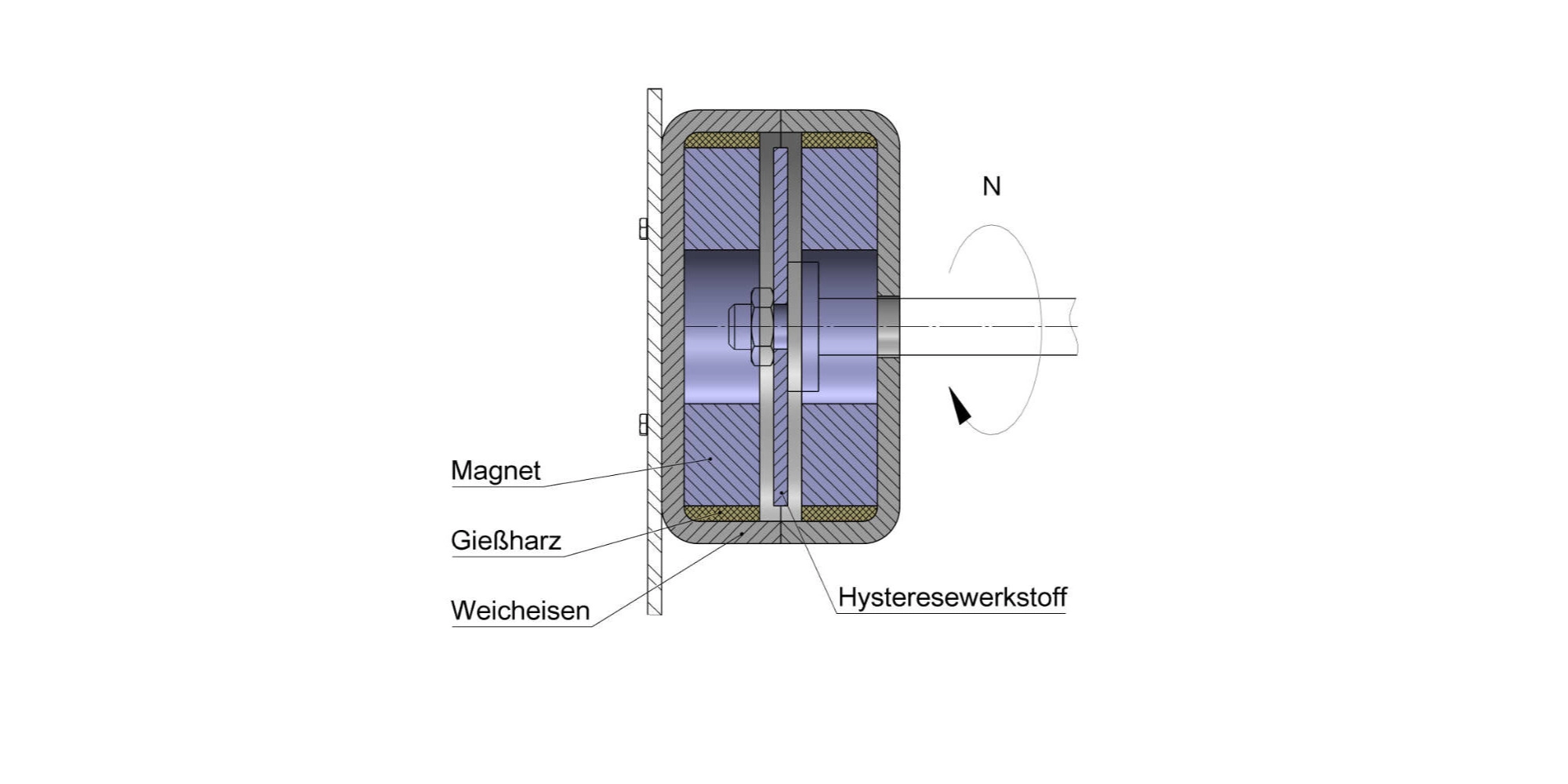

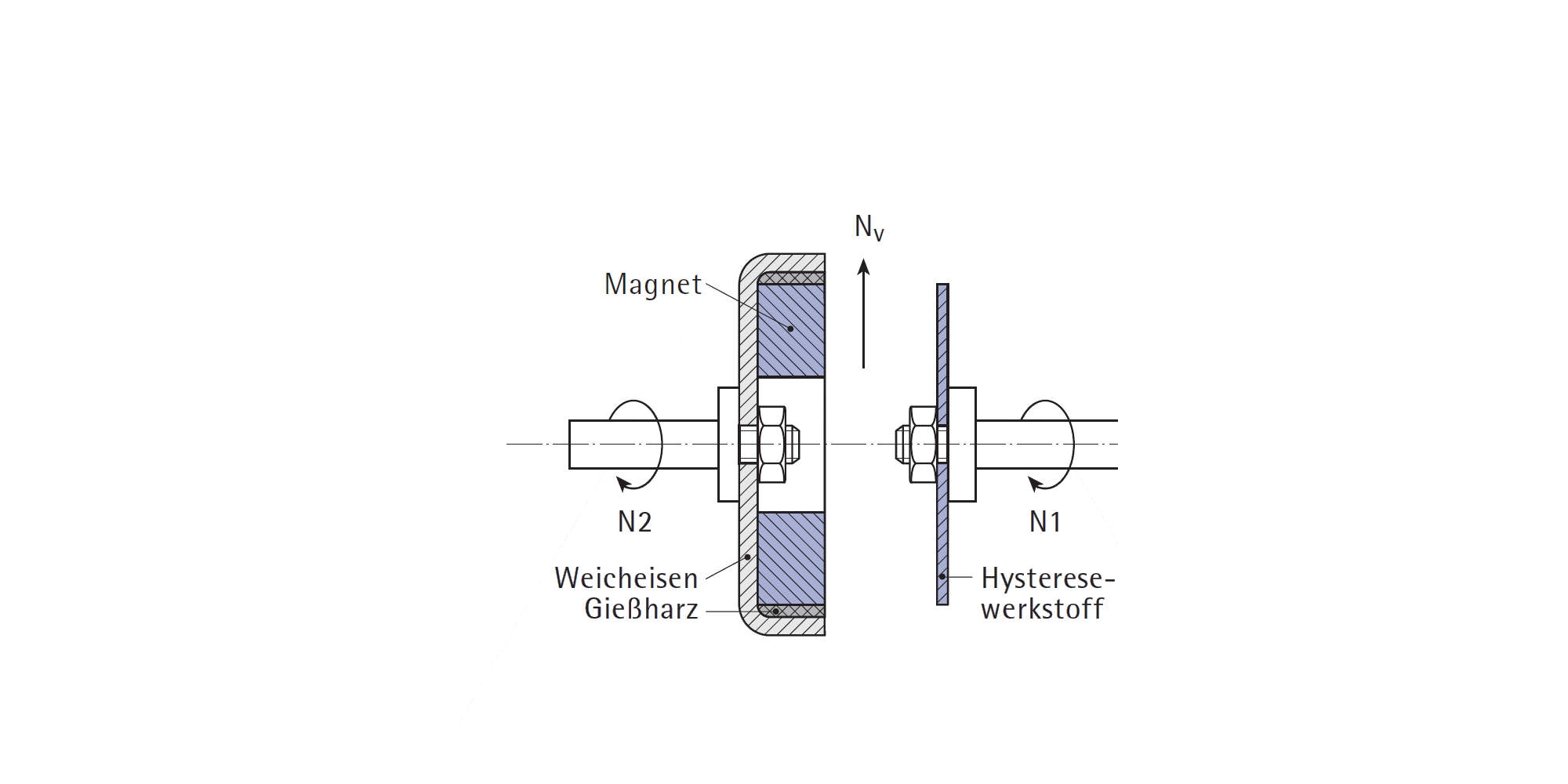

In the hysteresis brakes built by Tridelta, a non-magnetized hysteresis disk is opposed by a permanent magnetic disk. Depending on the application and the desired torque, the material combinations can be varied, e.g. AlNiCo 12/6 for the hysteresis disk and Neolit NQ3F for the magnetic disk.

The braking torque is largely independent of the relative speed between the two discs and is already fully present at very low speed. A small air gap exists between the discs. If necessary, this can be changed, resulting in easy controllability of the torque.

The adjustable hysteresis brake manufactured by Tridelta is particularly suitable for unwinding wires. The maximum adjustment range of this brake can be additionally varied by selecting the magnetic material.

The hysteresis brake with variably adjustable braking torque is preferably used in the tire or textile industry, where a wide range with different continuous material is used. The brake with fixed braking torque is used in packaging machines, for tension control or as a holding brake.

Versions

Tridelta supplies hysteresis brakes in various dimensions with different braking torques.

Variable adjustable braking torque

- Application: Tire and textile industry

- Desired braking torque mechanically adjustable

- Maximum braking torque can be changed by selecting the material for the magnetic and hysteresis disk

Braking torques: up to 35 Nm as standard, above this after consultation

Fixed braking torque

- Application: Packaging machines, tension control, holding brakes, beverage filling lines

- Change of braking torque possible by means of spacers between hysteresis and magnetic disk (requires opening of housing)

- Maximum braking torque can be changed by selecting the material for the magnetic and hysteresis disk

- Braking torques: up to 15 Nm as standard, above this after consultation