Magnets AlNiCo

The material for temperature-resistant permanent magnets.

AlNiCo magnets are used in applications where magnets of the highest temperature resistance are required.

In this area, Tridelta offers the aluminum-nickel-cobalt magnet, which was developed some 90 years ago and has been repeatedly improved to reflect the current state of the art. Today, AlNiCo materials are a byword for high-quality magnets with the maximum temperature resistance up to 550°C.

Features / Advantages

- Cost-effective

- Suitable for high temperatures

- Corrosion resistant

Application areas

AlNiCo magnets have various areas of applications. For example, they are suitable for:

- Electricity meter

- Ground fault circuit interrupters

- Relays

- Sensors

- Motors

- Adhesive applications

- Measurement and control technology

- Process automation

Magnet production

The temperature-resistant AlNiCo magnets are manufactured by melting and casting alloys or using powder metallurgical processes. There are several grades of aluminum-nickel-cobalt material from which both isotropic and anisotropic magnets are made. Their magnetic properties depend to a large extent on the size and design of the magnets. For this purpose, the AlNiCo powder mixture is pressed into moldings, which are then sintered at high temperatures in a vacuum or under inert gas. At the same time, the intended alloy is formed. The raw magnets are homogenized by heating them again and then cooled back to room temperature in compliance with precise time specifications. Finally, the tempering treatment takes place. To avoid oxidation, all heat treatment processes are carried out under inert gas.

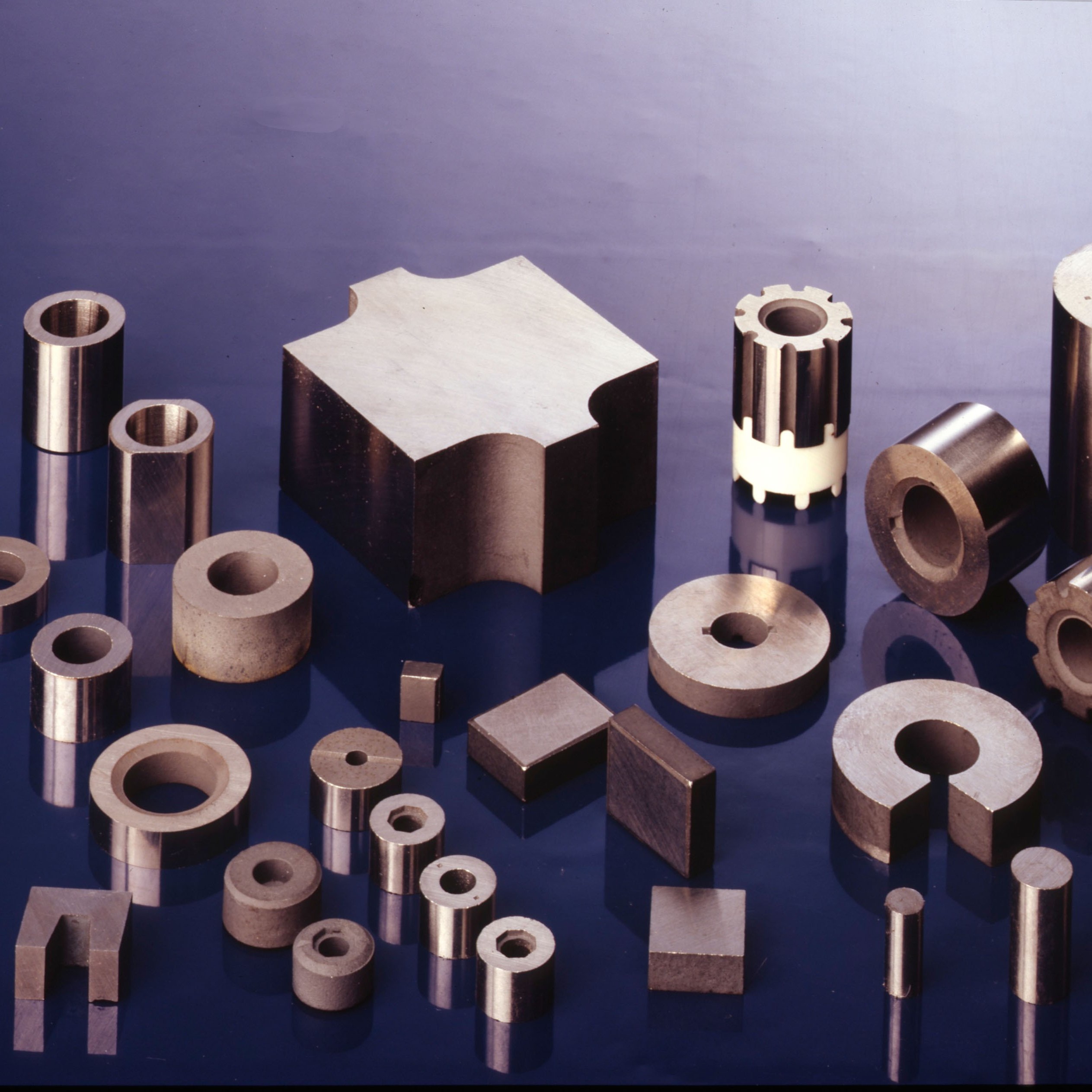

Magnet shapes

AlNiCo magnets from Tridelta can be manufactured in any desired magnet shape, which can be realized by powder metallurgical processes or by casting. Cuboids, cylinders, rings, segments or other shaped parts are supplied. Holes, recesses, grooves, etc. can also be made in magnets manufactured from powder – provided, however, that they run parallel to the pressing direction.

Temperature behavior

Magnets made of AlNiCo are particularly suitable for applications in which the magnetic field should be largely independent of temperature. This is because the magnetic values of AlNiCo materials are the least dependent on temperature of all permanent magnet materials. This is their particular advantage. Thus, the upper operating temperature is 550°C, but it depends on the location of the operating point. Some AlNiCo grades, especially AlNiCo 39/12, have been used successfully at even higher temperatures. Nevertheless, even low temperatures do not irreversibly affect AlNiCo magnets.

Chemical and mechanical properties

AlNiCo magnets are corrosion-resistant and insensitive to most acids. However, if they are to be exposed to inorganic acids and alkaline solutions, isolation is necessary. Due to the high brittleness of AlNiCo magnets, impact stress must be avoided when screwing or reinforcing. When assembling with different materials, the different expansion coefficients must be taken into account. Magnetized magnets, for example, attract iron filings and dust. Therefore, it is recommended to magnetize the magnets only after mounting.

Magnetic properties

AlNiCo magnets can be used in a wide temperature range from -270°C to +550°C. This advantage comes at the cost of low magnetic stability against external fields and temperature influences. However, after artificial aging or low shear, AlNiCo shows the smallest reversible changes in flux density of all materials.

Cast AlNiCo magnets offer slightly better magnetic properties than sintered magnets.

1) Designation based on DIN 17410/IEC 60404-8-1

2) The maximum possible operating temperature depends on the dimensioning of the system.

i = isotropic, a = anisotropic