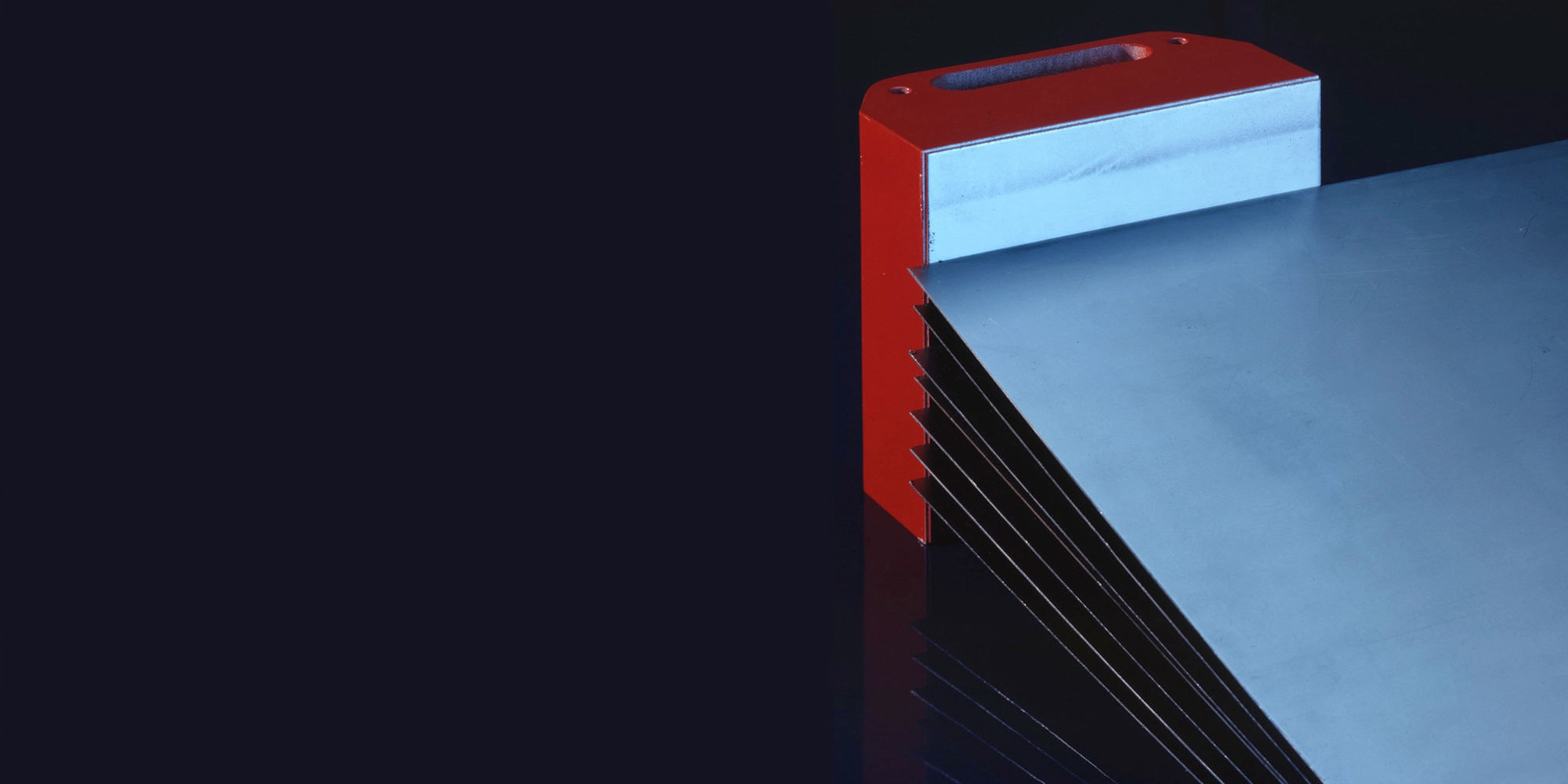

Permanent magnet spreader

Are currentless, reliable and low-maintenance devices,

which separate the sheets using magnetic force without incurring follow-up costs and can be individually adapted to different requirements.

Permanent magnet spreader

Permanent magnetic spreaders work without electricity, the sheets are separated by magnetic force alone. Permanent magnet spreaders are therefore fail-safe, low-maintenance, sustainable and do not incur any follow-up costs. Individual solutions are possible with the help of different magnet arrangements.

In addition to bearing types, Tridelta offers other dimensions of permanent magnet spreaders. Depending on the sheet thickness and adhesion forces due to liquids such as greases or oils, the sheet metal lifters can be made with appropriately adapted magnetic materials.

Application area

The permanent magnet spreader is suitable when

- sheets in stacks up to 6 mm thick are to be separated

- wear-free operation and operational safety without energy supply is desired

Versions

If a desired product is missing from the list, for example sheet metal lifters for round or asymmetrical sheets or special designs with a swivel arm, please contact Tridelta regarding specific solutions.

Functionality

Magnets pass a strong magnetic flux through the side of the stack of sheets and magnetize the individual sheets with the same polarity. Since like poles repel each other, the sheets are lifted by the force of the magnets alone. Accident hazards inevitably associated with unstacking, gripping and inserting steel sheets are significantly reduced.